Human Capital Management Finds Value Using Supply Chain Management Tactics

This article is a companion piece our Podcast with Andrew Lobo, “The Future of Supply Chain Talent Management.”

Introduction – Why compare Supply Chain Management to Human Capital Management?

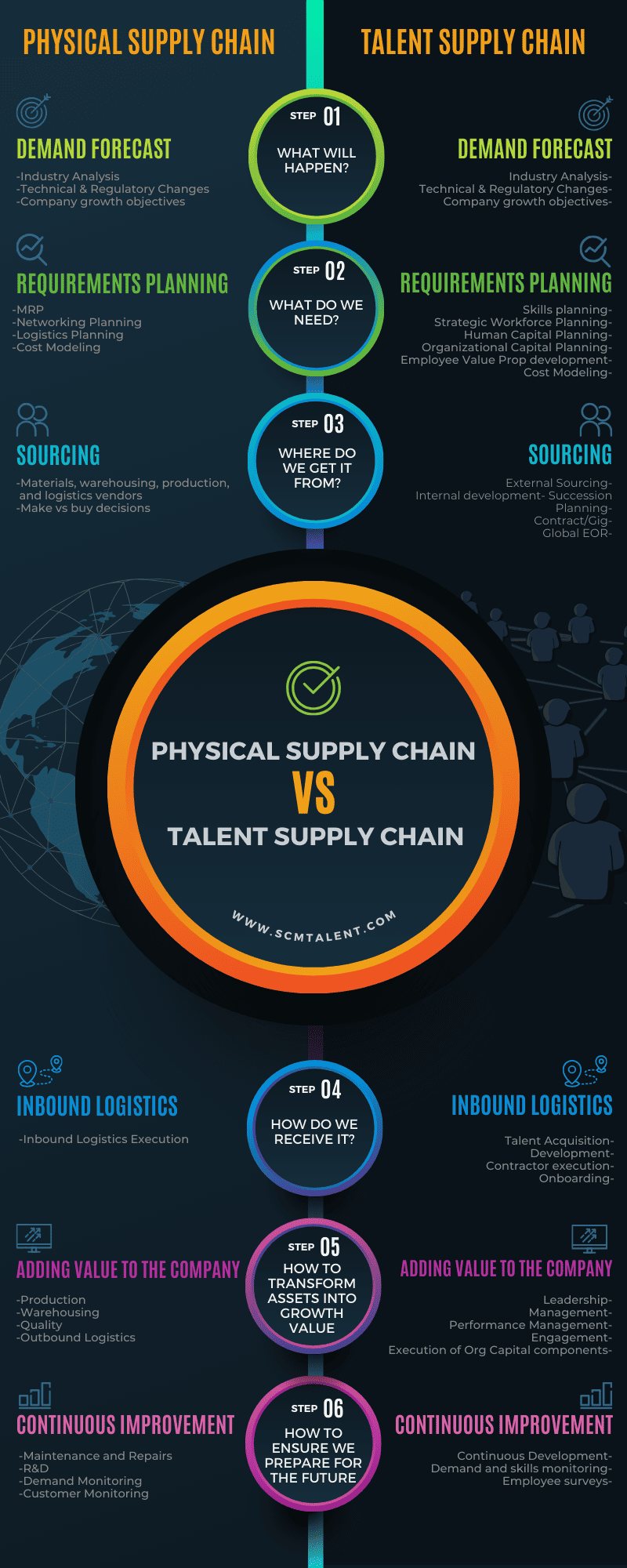

The purpose of this article is to examine the various aspects of supply chain management (SCM) and suggest that many of the tools, processes, and technologies could be useful inspiration for how we manage talent. By leveraging established methods used in SCM we can potentially improve how we manage talent.

The current US GDP is approximately $27 trillion. Of this, depending on the specific measurement method used, approximately 75% is services based and 25% is based on the production of goods and materials.

Despite the overwhelming majority of GDP being services based, the processes and technology relating to the management of the inputs of value creation is significantly more developed for manufactured goods and materials than it is for services – and has been for decades.

We will organize the article based on the primary steps in SCM.

Purpose of Supply Chain Management (SCM)

The purpose of SCM is to ensure you have sufficient, but not excessive, supply of the critical inputs you need to produce products. This purpose translates directly for Human Capital Management (HCM). That is, ensuring we have sufficient – but not excessive – talent to deliver the services that create value.

Forecasting Demand

The first step is always understanding demand. This is the same whether for products or services, and includes analysis of customers (new, existing, attrition etc.), the amounts they will order, as well as macro economic factors. The output of the demand forecast helps scale overall capacity.

Planning

Once overall demand is established more detailed planning occurs. In SCM, this is generally referred to as Sales and Operations Planning-or Sales, Inventory, and Operations Planning (SIOP). The goal of SIOP is to ensure that every area of the company involved in production is ready to execute based on the forecast.

There are 4 areas of SIOP that are often under-considered when it comes to HCM.

- The first is the cross-functional nature of SIOP – by definition it includes both sales and operations, but in practice it also involves finance, procurement, and other functions. With HCM, the planning should also include multiple functions in addition to HR. Including finance, strategy, marketing and will help provide a more comprehensive and cross-functional HCM strategy.

- The second is that SIOP is not static. The SIOP plans are constantly monitored for changes to relevant assumptions and adjustments made as needed. Similarly, changes to the assumptions made when planning talent needs also may require adjustments to the plan.

- The third consideration is if there is a new or changed raw material, then the impact on operations should be considered. In HCM, if a new skill or capability is required, a company may need to change certain aspects of how it sources and manages talent.

- Last, in addition to planning for the direct operating requirements, explicit planning for the supporting elements is also planned. This includes planning for maintenance, cleanup, utilities etc. For talent this means not only planning to either acquire or develop your people, but also to plan for the supporting areas to help them perform. This could include culture, tools, leadership style, work environment etc. All of these considerations should be included in Strategic Workforce Planning.

Sourcing and supplier management

Sourcing involves finding the raw materials a company needs to produce the value-added outputs. Part of sourcing includes developing a supplier network. Within an overall supplier network a company generally has Strategic Suppliers. These are the suppliers that provide raw materials that are generally critical to production AND are difficult to find. Both conditions must be met in order to establish strategic suppliers. With HCM, this translates to roles. What roles are critical to the company’s value creation AND are difficult to find. While search firms, staffing agencies, BPO providers and others may be considered as strategic suppliers – often the best “strategic supplier” is the company itself. By having a very strong Learning and Development group plus a robust employee assessment process, companies can develop their own talent for critical and hard to source roles. This is similar in SCM to a company’s make or buy decision – if the raw material has high criticality and low availability, the company may decide to make it themselves.

Procurement and Inbound logistics

Once forecasts and plans are made, raw materials need to be ordered and delivered to the company. While it could be tempting to simply state the parallel for HCM here is Talent Acquisition and onboarding, in practice it is a bit more involved. First, if the role you are sourcing is a critical role and you are “making” it yourself – then an accurate understanding of development cycle times and succession planning is critical. If you are sourcing the talent externally you must understand your talent suppliers’ lead times. Similarly, onboarding is often underleveraged. In SCM, materials are generally inspected for quality and other specifications upon arrival, and they may undergo several procedures to prepare them for production. Onboarding talent should be considered similarly. How do we prepare people to be effective in their roles as quickly as possible?

The Future of Supply Chain Talent Management

Operations/Production

The key parallel here is that in SCM production is not static. It is constantly monitored. This is the same for Talent as they are performing in their roles. This analogue fully supports the concept of daily performance management, rather than once a year.

Inventory – Just In Time (JIT) and Lead Times

One of the classic problems in SCM is inventory levels. Companies must balance having sufficient product to deliver to customer requirements, but not too much that will negatively impact cash flow and may lead to obsolescence. SCM concepts that address this issue include just in time (JIT), lead times, and safety stock. JIT means having sufficient product available at the moment it is needed, and no more. To do this well means understanding lead times – how long does it take to procure, produce, and ship product. The shorter the lead times, the easier it is to do JIT. Even if companies do this well, there may still be unforeseen circumstances that cause lead time delays. Because of this, many companies have safety stock. This is an amount of inventory to prevent out of stock situations should lead times be interrupted.

JIT also applies to HCM. Companies want the right talent at the right place at the right time. To do this they must understand the “lead times” for talent – either externally through talent acquisition, or internally through learning and development and succession planning. Understanding these lead times is critical to improving the effectiveness of Strategic Workforce Planning.

Technology

Over the years there have been several technologies that have fundamentally improved SCM performance. These include bar codes, RFID, MRP systems, Robotics and automation. Each of these technologies has a direct impact on SCM effectiveness. With HCM Human Resource Information Systems, Applicant Tracking Systems, Learning Management Systems have also helped improve speed and effectiveness. AI promises to impact both areas.

Conclusion – and an important caveat.

This article illustrates opportunities for HCM to improve by taking cues, insights, and inspiration from SCM. The parallels are quite clear. There is one thing that should be kept in mind when considering the extent of the analogy: products and materials are things, they are inanimate objects. They cannot get annoyed or disgruntled. They do not get happy or sad. People, of course, have brains, emotions, assumptions etc. Because of this, the impact of processes, tools and technologies in SCM will always be more predictable, measurable, and precise than similar tools and processes applied to HCM.